In early 2010 I purchased a 18K mile 2007 LS4/4t65e-hd dropout and started work on an LS4/F40 swap to replace my old Ramjet one. The goals were 100 more hp, 100 lbs less weight, and 30 mpg.

The first engine start was 2/10/2013 and the swap was first driven on 3/3/2013. As of July 2019, the swap has 53K miles on it and I continue to drive the car daily 9 months of the year. It is by far the most enjoyable Fiero I have ever had or have driven!

This car was also identified as one of 10 insane powertrains on the 2019 hot rod power tour: https://www.hotrod.com/articles/10-insane-powertrain-combos-hot-rod-power-tour/

Build details:

• 2007 LS4 with E67 ECM – 18K miles

• 4” cold air intake

• LS7 MAF & Exhaust Manifolds

• LS2: 90 mm Throttle Body, Intake Manifold, Fuel Injectors

• 224/232 .574/.575 DoD compatible camshaft, pushrods, and valve springs

• 2006 F40 6 speed manual – zero mile unit, upgraded with 3.091 Final drive

• 10” Spec Stage 4+ Clutch

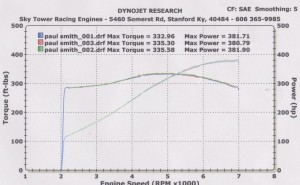

• 382 whp @ 6800 rpm, 335 wtq @ 5000 rpm, 22 mpg on daily commute, 29 mpg on interstate

• 2807 lbs curb weight, 608/609 front corners weights and 794/796 rear corner weights

• 12.896 @ 114 best ¼ mile performance so far – Needs a driver mod…

The 2 main challenges with the LS4/F40 were:

• Starter was transmission mounted – no starter provision on the F40 6 speed manual

• LS4 used a 142 tooth ring gear and only came with an auto – no off-the-shelf flywheel

At the time I started this swap, no one had a solution for either the starter or flywheel issue. My first plan of attack was to develop a bolt-on starter bracket for the F40 using the stock LS4/4T65 starter location. I posted a youtube video showing my starter solution spinning over the LS4 on Sept 6th, 2010. I solved the flywheel issue on March 28th, 2011 by designing and machining a new aluminum flywheel to use a 10” clutch.

The rest of the swap was an exercise in fabrication as there were no off the shelf parts available for this swap. It took about 3 years working off and on to complete it. Since it has been completed, it is by far the most enjoyable Fiero I have ever had or have driven.

List of most of the fabricated parts:

• 2 x 3 cradle cross-members

• Custom 4 corner engine/transmission mounts using rubber lower control arm bushings

• Custom accessory drive to relocate the alternator out of sight

• Custom billet belt tensioner arm

• Extensive reworking of the stock LS4 water pump assembly

• Custom bolt-on starter mount

• Custom 12# aluminum flywheel

• Custom coil relocation brackets and smoothed the coil bosses off the valve covers

• Custom bent hard line for PCV

• 4” cold air intake tube with LS7 MAF mounting bracket

• Custom intermediate shaft for the passenger axle

• Custom axle tripod on the driver side

• Custom shifter bracket and reverse lockout

• Smooth firewall panel

• Removed the hinge boxes and used custom hinges to support the decklid

• 500 connector harness and tail light harness removed from engine bay

• Custom engine harness to keep as many wires as possible out of sight

• Custom stainless steel exhaust